Knowing the Solar Panel specifications, helps us understand the difference between different kinds of panels and compare which one is best suited for us.

All vendor claims their solar panel to be superior or equivalent to reputed makes. Not understanding the solar panel specifications make it very confusing to understand who is true.

Most people don’t understand the solar panel specifications and even if you understand few terms still it’s difficult to evaluate. Because you don’t know how much importance is to be given to which parameter.

Another problem in the solar industry is that most of the salesman hardly know much about solar specifications and as such give inaccurate statements.

So, here’s a crash course for you to understand the specifications of the solar panel. You will never get fooled by any vendor, once you go through these contents.

72 Cells or 144 cut cells which is better?

A solar module contains several solar cells connected in series. The voltage of the solar panel should be higher than the voltage of the battery so that it can charge the batteries. 36 Cell panel is called 12 V nominal panel since it is designed to charge 12 V battery. Nowadays, mostly 72 cells panels are coming that are designed to generate 39.6 Volts and are called 24 Volt nominal solar panels.

The new technology that has come is half-cut cells. In this technology, the solar cells are cut in half. When the cells are halved the current of the cell is also halved, which decreases the resistive losses. Cut cells have a better output rating and are more reliable and efficient than the traditional panels. Thus 144 cut cells are better than 72 cells.

For further read refer to the blog: What is a half-cell solar panel?

PERC Modules or standard modules which is better?

The standard modules have losses due to one or more of the following reasons: a. Light passing through the cell to become heat, b. Light is reflected back, c. Electron recombines in front or rear or reaches rear contact.

PERC Modules: PERC stands for “passivated emitter and rear contact”. PERC cells have an additional layer on the back of the traditional solar cells. This results in more absorption of sunlight, mitigate rear combinations and prevent longer wavelength from becoming heat. PERC modules generate 5% more output than standard solar cells considering the 20% efficiency of the module. For reading further refer to the blog: What You Need to Know About PERC Solar Cells

Own manufactured cells or purchased cells which is better?

The solar cell manufacturer is not mentioned in the solar panel specifications. All the top brands make most or all of their own solar cells in their panel, as the quality of the panel depends on the quality of the cells in it. It is always preferable to go with the vendor making its own solar cells.

Mono-Crystalline or Polycrystalline which is better?

The polycrystalline solar panels have an efficiency of 15% to 17% and power ratings of 300w to 335 W.

The efficiency ratings of the mono-crystalline solar panels are higher(17% to 22%) and also have higher power capacity ratings (375W to 445 W). Hence, Mono-crystalline solar panels are better but they are costlier too.

For further read refer to the blog: Types of solar panels: which one is the best choice?

PID Resistance, What does this mean?

PID stands for ‘Potential Induced Degradation. The PID free panels are free from the loss due to the PID effect.

Cause: This problem can arise when a voltage difference occurs between the panel and the earthing. For safety reasons, the solar panel is earthed, which can cause a harmful potential difference between the earthing and the voltage generated by the panel. In some cases, this generates a voltage that is partly discharged in the primary power circuit.

Effect: The consequences of this effect are an ongoing reduction in performance and accelerated ageing of the PV panel.

Understanding STC AND NOCT

Under the datasheet, you will see the datasheet containing the electrical parameters under STC. What does this mean? Let us understand what is meant by STC first.

Power Ratings under STC doesn’t give a true picture.

STC Power Rating: STC stands for ‘Standard Test Condition’.

Nominal Power at STC means the expected power of the panel when tested under Standard Test Conditions. All the Panels are rated under standard testing conditions and are labelled based on the output power generated from the panel. This makes the comparison of the panels between different brands and different panels among the same brand uniform for the consumer.

Under STC the following solar panels are tested under the following conditions:

- The irradiance( solar power falling per unit area) is set to 1000 W/m2.

- The solar irradiance angle of 45o

- The module temperature and ambient room temperature are both set to 25oC.

- Air Mass of 1.5 (AM1.5) spectrum

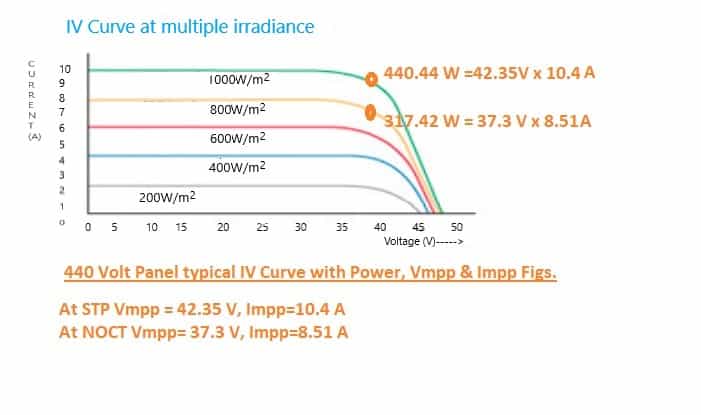

For example, the panels of 440W Nominal Output at STC means that it will generate 440W of power under STC conditions.

This nameplate value makes it easy for different panels and system sizes to be compared.

However, the actual conditions at the installation sites are much different to the STC conditions and hence the STC condition doesn’t give a correct picture of the solar power output from the panel. The actual power output from the panel is much lower than the STC rating.

NOCT Power Rating are more realistic but can’t tell what power you will get.

NOCT stands for Nominal Operating Cell Temperature.

NOCT value of maximum power of the solar panel gives the power the solar panel will generate under a more realistic testing condition when they will be installed at the site. Hence, the NOCT value gives a better idea of the power you will get from the panel in actual site conditions.

The NOCT values are taken as follows:

- The irradiation of 800W/m2.

- The solar irradiance angle of 45o

- The module temperature of 45+/-3 oC.

- The Air Temperature of 20oC.

- The Airspeed of 1 m/s cooling the back of the tilted solar panel.

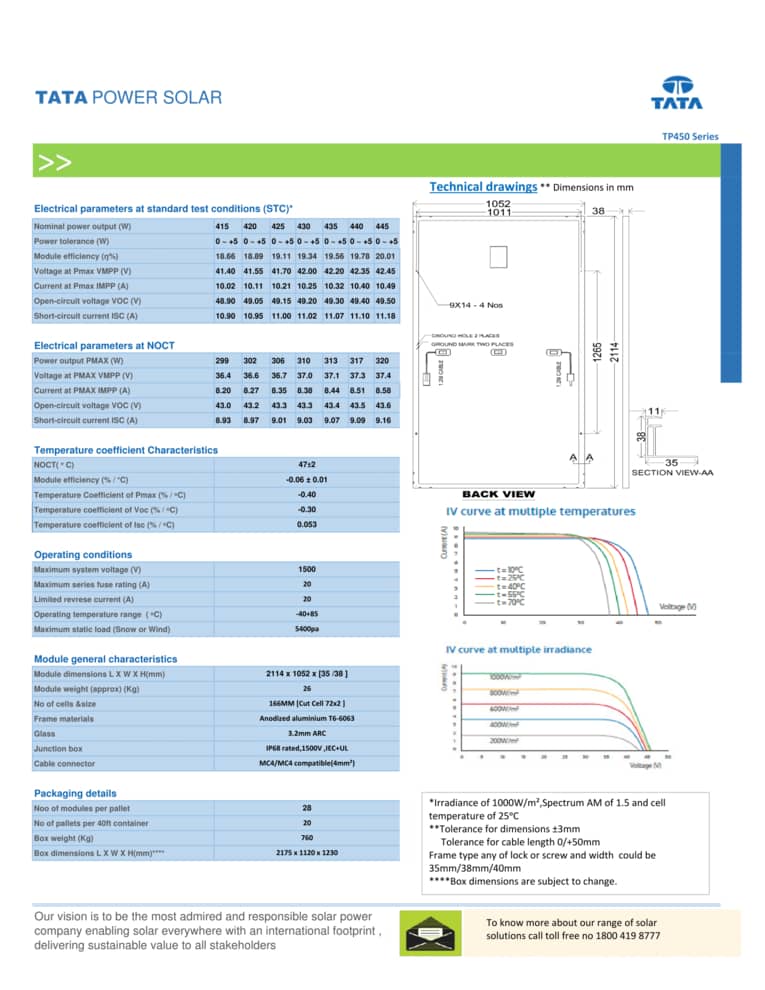

For example, the panels of 440W STC nominal power will mean that under NOCT with Temperature taken as 47 +/- 2 oC it will give an output of 317 W (can be found by seeing the technical leaflet of the solar panel).

As a user, you are concerned with the energy that you will get in the year from the solar panel in your location. This we will take up in the last after understanding the various effects on the solar panel.

Understanding Temperature Coefficient Rating (in %/oC):

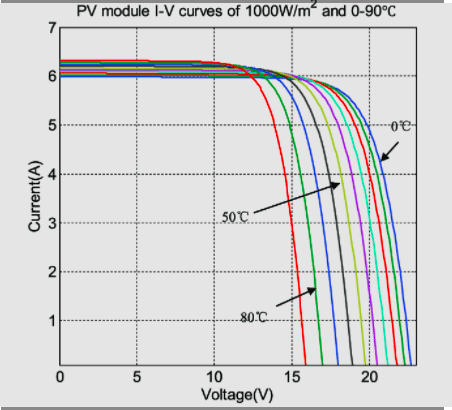

The higher the atmospheric temperature, the lower is the energy generation from the solar cells. Solar panels work more efficiently in cold temperatures.

The Increase in temperature reduces the bandgap of a semiconductor, like other electronics, solar panels work more efficiently in cold temperatures.

In a solar cell, the parameter most affected by an increase in temperature is the open-circuit voltage.

As the temperature rises, the panel generates less voltage and becomes less efficient, producing less electricity.

The temperature increase can affect the solar panel efficiency by 8%-15%.

Under the heading of Temperature and Coefficient Characteristics, you will find a value given under Module efficiency (%/oC).

This tells the % difference the temperature will have in peak output power with the change in the temperature.

The temperature increase can affect the solar panel efficiency by more than 15%. Hence it has a big impact on the actual solar panel power output.

So to estimate a more realistic value, we have to calculate the module power losses under operational conditions.

To determine the effect of temperature on production, the datasheet of the manufacturer mentions the temperature coefficient.

The temperature coefficient expresses the effect of the module temperature deviation from 25°C.

In general, for each degree above 25 degrees (known as a standard testing condition, or STC), your panel will become one per cent less efficient. For each degree below 25 degrees, it will become one per cent more efficient. The formula for power loss is as follows:

POWER LOSSES (%)= T COEFFICIENT X (NOCT – 25 ºC)

The manufacturer also gives the IV Curve at multiple temperatures, from which also the change in the voltage and hence power can be found out.

To understand it in more clarity let’s take an example of a datasheet of a solar panel below:

The STC Power of Module = 440 W,

Module Temp Coefficient% = (-0.06+/-0.01)/oC,

NOCT temperature = 47 +/-2.oC.

so at 47oC, the output loss will be

-0.06 x (47-25)= 1.32 % loss

So the power loss at 47 oC= 440 x 1.32% = 5.8 W due to the temperature difference.

Understanding PV Module Efficiency

Under the heading of ‘Electrical Parameters at Standard Test Conditions (STC), you will find a row mentioning module efficiency (n%).

This tells what is the power density of the solar module.

This tells how much area the panel takes to produce the given power output.

Efficiency% = (Module Wattage/(LXW of module in m) X100/1000 W/m2))

Eg. Efficiency under STC of a 440 W Mono Module of size 2114 mm x 1052 mm will be:

= {440 /(2.114 x 1.052)} x (100/1000)

= 19.78% under STC

Efficiency under NOCT of above 440 W mono module, if NOCT Pmax is 317W, will be

=317/(2.114 x 1.052) X 100/1000

=14.25%

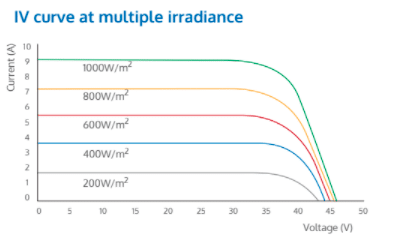

Understanding Solar Irradiance and its effect on the Solar Panels

The solar irradiance is the solar power falling per unit area so is measured as W/m². The irradiance of the location greatly affects the power that will be produced from the panel. The solar irradiance varies from time to time and season to season on a place. The higher the irradiance the higher will be the power per unit area from the panel. The below graph shows the effect of solar irradiance on the power output from the panel.

Understanding Open Circuit Voltage (Voc)

It is the maximum voltage that the solar panel can produce with no load on it, and hence there is zero current. It is measured across the open ends of the wires attached to the panel with a multimeter.

If two or more panels are connected in the series then it is measured by the sum of their voltages(Voc1 + Voc2 + ….+Vocn). The sum of the voltage of panels in series + approx 3.5% should be less than the maximum voltage permitted by the solar charge controllers.

Voc is briefly reached in the early morning when the sun has just reached the horizon, the panel is still cool and the connected electronics are still in sleep mode.

The Voc at NOCT is a little lower than VOC at STP due to the solar radiation difference.

It is important to understand that the overcurrent can be checked by fuse or breakers but not over-voltage, so if overvoltage is put the electronics will get damaged.

Understanding Short Circuit Current (Isc)

It is the current produced by the solar module when the voltage across the solar module is zero, i.e., when the circuit is short-circuited.

It is measured by passing the current through a multimeter by joining the positive and negative terminals of the panel with no load ( short-circuited) and hence zero resistance.

It is the largest current that can be drawn from the solar cell.

The short circuit current is dependent on the intensity of light falling and the collection of charge in the cell carriers.

The Isc at STP and NOCT is given in the specifications sheet. It is obviously higher than the Isc at NOCT because the solar irradiance is lower at NOCT.

The inverter or solar charger should be able to handle 1.25 times the Isc at STP.

Understanding Maximum Power Point (Pmax)

It is the point where the power (Power=Volts X Ampere) is highest. It is the sweetest point of the solar output.

The MPPT charge controller or Inverter tries to keep the Power maximum.

This is the point located at the knee of the IV curve of the panel.

Pmax can be found from the formula Pmax = Vmpp x Impp.

Understanding The voltage at Maximum Power Point (Vmpp)

It is the voltage at the point where the power output is maximum(Pmax).

It is the voltage that you want to see when connected to the MPPT solar controller (like MPPT solar charger or Inverter).

The Vmpp varies throughout the day with the change in power. The shading, soiling of the panel surface etc. also have a lowering effect on Vmpp.

The voltage can be measured with a multimeter by measuring the voltage at the input terminals of the MPPT controller device

The Vmpp at STC and NOCT both are given in the leaflet specifications. The STP Vmpp tells the voltage which can get at STP conditions and the NOCT Vmpp tells the voltage which you can get at the NOCT conditions.

Understanding Current at Maximum Power Point (Impp)

It is the current produced when the power output is maximum Pmax.

Similar to Vmpp it is the current you want to see when connected to the MPPT controller (like MPPT solar charge controller or inverter).

The Impp also varies throughout the day, depending on the intensity of the light falling on the panel.

Understanding Power Tolerance (why it’s important)

Power Tolerance is a measure of how much power the panel can produce above or below its rated capacity at any time.

So, a 330 W panel with a power tolerance of +/-5 W will give an output of 325 to 335 W.

A 330 W panel with a power tolerance of +/-0 will give an output of 330 W.

A 330 W panel with power tolerance of +5/0 will give an output of 330 to 335 W.

This is an important factor while considering the selection of the solar panel. You should purchase the panel above or equal to the rated panel capacity.

During the manufacturing of the panel, the panels are exposed to a 1000W/m2 flashlight (1-30 ms of light), as a substitute for sunlight. The panels are then sorted according to the measured value with 5% accuracy.

Now in the case of 335 and 325 W panels, one may operate at 335 W (38.2 V x 8.877A) and the other may operate at 325 W(36V x 9.03A). Even if the wattage is the same there can be a difference in the volts and current 330 W (37.4V x 8.82 A) or (37V X 8.9 A).

The voltage of the solar panel array in series is the total of voltages of individual power panels, so the voltage difference doesn’t make much difference. However, the power produced at different current levels results in system loss. This is known as solar panel mismatch. This excessively heats the solar cells resulting in power losses and accelerated solar panel degradation.

An Mpp tracker combines the series of mismatched current solar panels and supplies the effective MPP at the string level.