Though the carcass of kitchen plays a key role in the lasting and long life of the kitchen, its importance often gets overlooked and ignored among other kitchen priorities of the user.

The carcass provides the structural support and foundation for the kitchen cabinets, drawers, shelves, and counter tops.

Here, we will do a comprehensive analysis of the kitchen Carcass, covering all that you might have wanted to know about it. We will cover the following topics in this post:

- What is a carcass ?

- Key Functions of Carcass

- Different Materials used in carcass and the advantage/disadvantage of each

What do we mean by Carcass??

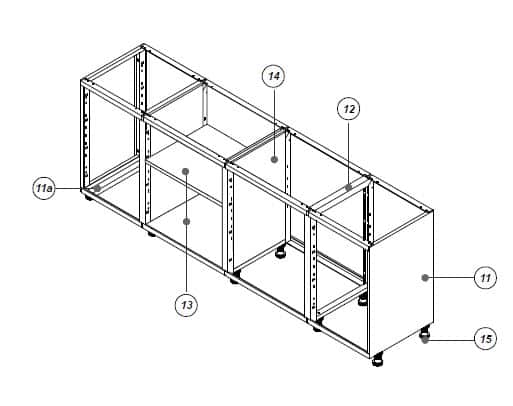

- Carcass, refers to the structural framework of the furniture, on which the entire kitchen stands. It includes the walls, base, and back panel of the cabinet.

- The Carcass bears the total kitchen load and like the foundation of the building it provides strength to the kitchen furniture

- The doors, drawers, shelves, and kitchen top are all held in place by the kitchen carcass.

- The carcass of the kitchen remains hidden from view as they get covered by the shutters or the door covers.

- The Carcass of a kitchen is made of different materials by different kitchen manufacturers.

- Few of the common materials used to make carcass are MDF Board, HDF Boards, particle board, commercial plyboard, WPC/PVC board, BWR Marine Ply, BWP Marine Ply, granite stone slabs, Aluminium channels & Galvanized Steel etc.

5 Key Functions of Carcass:

The Carcass plays 5 crucial functions in a modular kitchen:

Structural Support:

The carcass provides the necessary structural support for the various components of the kitchen, ensuring that they remain stable, secure, and level. It helps distribute the weight of the kitchen cabinets and countertop evenly, preventing them from sagging or collapsing over time.

Durability:

The carcass determines the overall durability and lifespan of the modular kitchen. A well-built carcass made of sturdy materials can withstand the wear and tear of daily use, resist moisture, and prevent damage from pests, such as termites or ants.

Functionality:

The carcass design and configuration can impact the functionality of the kitchen. A well-designed carcass can maximize storage space, improve accessibility, and enhance the overall efficiency and workflow of the kitchen.

Aesthetics:

Although the carcass is not visible once the cabinets are installed, its quality and finish can affect the overall appearance of the kitchen. A well-finished and aesthetically pleasing carcass can enhance the look and feel of the kitchen, making it more appealing and attractive.

Stability:

The carcass acts as a framework to which other components of the kitchen furniture are attached. It provides a sturdy base on which the doors, drawers, and shelves can be mounted. This ensures that the cabinet structure remains solid and stable. The carcass is designed to be rigid, meaning that it does not flex or bend easily. This helps to maintain the shape of the cabinet and prevent it from warping or bowing over time.

CARCASS MATERIAL AND ITS ADVANTAGE & DISADVANTAGE:

We will analyse the advantage/ disadvantage of different kinds of materials used in making the Kitchen Carcass here.

MDF Board

Advantages:

- Smooth surface and uniform density make it easy to cut and shape for different cabinet configurations.

- Cost-effective and readily available

- Good option for painted finishes as it doesn’t have any prominent wood grain.

Disadvantages:

- Not as durable as other materials, and it can easily scratch or dent.

- Not water-resistant, can swell and deform when exposed to moisture.

- It may release formaldehyde and other chemicals in the air, which can be harmful.

- Has low Torque resistance and is brittle so not good for fixing screws.

HDF Board

Advantages:

- More dense than MDF, hence can be stronger and sturdier

- Has a smoother surface finish than particleboard and can be used as a substrate for laminates

- Can hold the screws tightly has good torque resistance

Disadvantages:

- Like MDF, it is not water-resistant and can easily get damaged when exposed to moisture.

Particle Board

Advantages:

- Cost-effective and readily available

- Easy to work with and can be shaped and cut easily

- Can be laminated with different finishes like wood veneer or PVC to give it an attractive look.

Disadvantages:

- Not as durable as other materials, and it can easily scratch or dent.

- Not water-resistant and can easily get damaged when exposed to moisture.

- Can release formaldehyde and other chemicals in the air.

- Low Torque resistance and brittle so not good for fixing screws

Commercial Ply Board

Advantages:

- Strong and durable, with good resistance to scratches and dents.

- More Water-resistant than above boards.

- Can be easily cut and shaped to fit different cabinet configurations.

Disadvantages:

- More expensive than particleboard or MDF

- Can have visible wood grain, which may not be desirable for some finishes.

- Can bend with time so not good for structural support and stability

- Water-resistance is better than above but not sutitable for kitchen

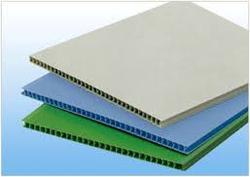

WPC Board

Advantages:

- Resistant to water and moisture, making it ideal for use in kitchens and bathrooms.

- Strong and durable, with good resistance to scratches and dents.

- Can be easily cut and shaped to fit different cabinet configurations.

Disadvantages:

- Can be more expensive than MDF and particleboard.

- Not as strong as plywood or solid wood.

- Not suitable for high-heat applications as it can melt and deform.

- Is Brittle and has low torque resistance so screws can tightened can loose with constant pressure.

PVC Board

Advantages:

- Resistant to water and moisture, making it ideal for use in kitchens and bathrooms.

- Easy to clean and maintain.

- Lightweight and easy to install.

Disadvantages:

- Can be more expensive than MDF and particleboard.

- Not as strong as plywood or solid wood.

- May have limited color options.

- Not good for structural support and stability

BWR Marine Ply

Advantages:

- Resistant to water and moisture, making it ideal for use in kitchens and bathrooms.

- Strong and durable, with good resistance to scratches and dents.

- Can be easily cut and shaped to fit different cabinet configurations.

- Good for Structural support and stability

Disadvantages:

- Can be more expensive than other plywood types.

- Can have visible wood grain, which may not be desirable for some finishes.

- Not Water Proof

BWP Marine Ply

Advantages:

- water and moisture proof, making it ideal for use in kitchens and bathrooms.

- Strong and durable, with good resistance to scratches and dents.

- Can be easily cut and shaped to fit different cabinet configurations.

- Good for structural stability and stability

Disadvantages:

- Can be more expensive than other plywood types.

- Can have visible wood grain, which may not be desirable for some finishes.

Granite Stone Slabs

Advantages:

- Durable and long-lasting, with good resistance to scratches and dents.

- Resistant to heat, making it ideal for use near stovetops and ovens.

- Easy to clean and maintain.

- Good for structural support, and stability.

Disadvantages:

- Can be expensive

- Brittleness makes it difficult to fix screws

- Tensile Resistance is good but retaining the fixed screw can be a problem with continuous change of pressure on screws due to movement of drawers

Aluminium Channels

Advantages:

- Lightweight and easy to handle

- Resistant to corrosion and rust

- Highly durable and strong

- Does not require any maintenance

- Can be easily shaped and cut according to the requirements

- Recyclable and environmentally friendly

Disadvantages:

- Can be more expensive than other materials

- May require special tools and equipment to work with

- May not be suitable for heavy-duty applications

- Not as good for structural stability as Marine Ply

- Torque resistance is low, the screws fixed on the carcass can become loose due to enlargement of hole

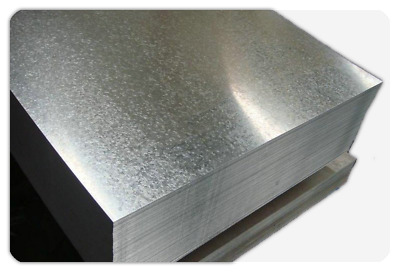

Galvanized Steel

Advantages:

- Strong and durable, with good resistance to scratches and dents

- Resistant to corrosion and rust

- Can withstand high temperatures

- Can be easily shaped and cut according to the requirements

- Does not require any maintenance

- Recyclable and environmentally friendly

- Good for Structural stability and Durability

Disadvantages:

- Can be more expensive than other materials

- Is heavier than aluminum or other materials

- May require special tools and equipment to work with

- Is Water Resistant but not water proof like BWP Marine Ply

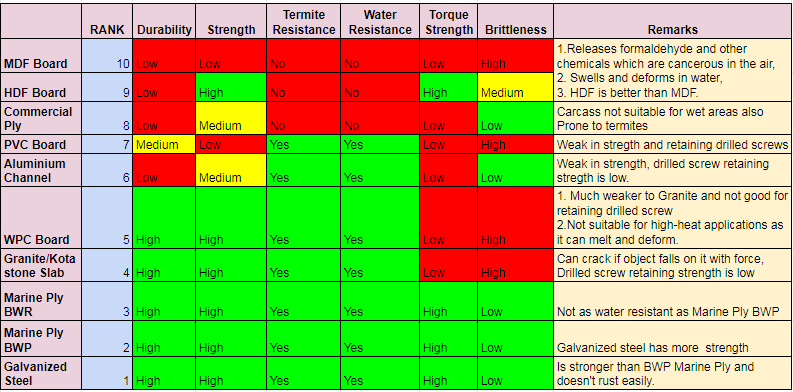

The table below shows the property of the carcass in a tabular form:

From the above it will become evident that the top three carcass are Galvanized sheet, Marine Ply BWP and Marine Ply BWR. Ideally you should not choose a carcass other than these three.

In summary, the carcass is the backbone of a modular kitchen, providing the necessary support, durability, functionality, and aesthetics. A well-built carcass is essential to ensure that the kitchen remains functional, durable, and aesthetically pleasing for years to come. It is important to choose the right type of carcass depending on your budget and needs.