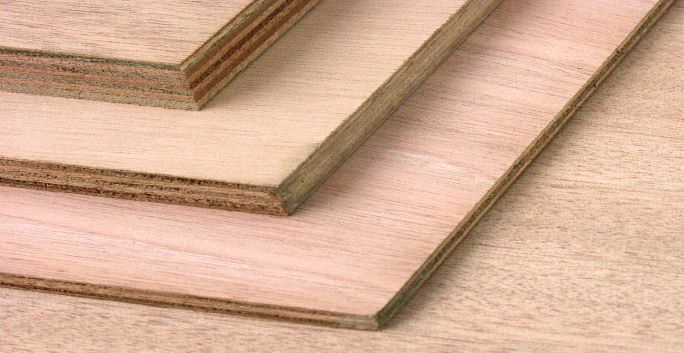

Modular kitchens are becoming increasingly popular due to their convenience and modern design. However, one of the key components of a modular kitchen is the use of plywood, specifically marine plywood.

Marine plywood is often marketed as the superior option due to its resistance to water, decay, and insects. However, not all marine plywood is created equal and vendors may try to deceive customers by making false claims.

In this article, we will provide tips from experts on how to avoid being fooled by marine plywood claims in modular kitchens.

The Marine Ply available in the market are of different kinds and grades. The Indian Standards to measure marine plywood are set by the Bureau of Indian Standards (BIS). The standards provide guidelines for the quality and performance of the plywood, including criteria for factors such as moisture resistance, strength, durability, bonding quality, and dimensional stability.

There are different standards for different kinds of plywood. In Marine Ply there are 4 kinds of plywood as below:

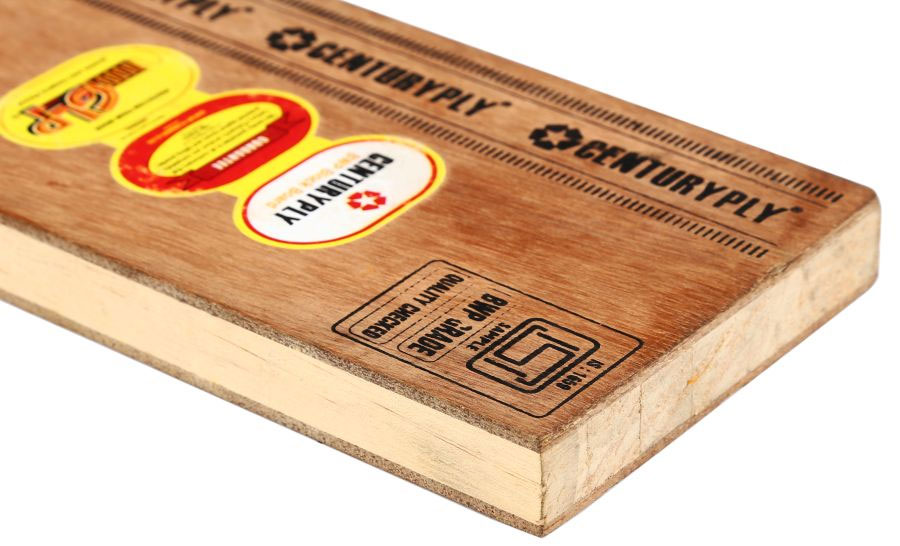

Marine Grade Plywood(BWP):

- This is the highest quality marine plywood available and is designed for use in extreme weather conditions, high moisture environments, and exposure to saltwater.

- IS 710 of the Indian Standard for marine-grade plywood defines the detailed specification and criteria for this grade of plywood.

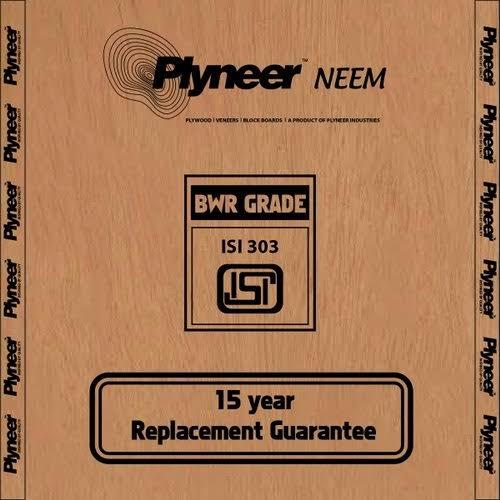

Boiling Water Resistant (BWR) Plywood:

- This type of plywood is suitable for use in interior and exterior applications and can withstand exposure to moisture and humidity.

- IS 303 is the Indian Standard for BWR plywood.

Moisture Resistant (MR) Plywood:

- This type of plywood is suitable for use in interior applications and can withstand occasional exposure to moisture.

- IS 303 is the Indian Standard for MR plywood.

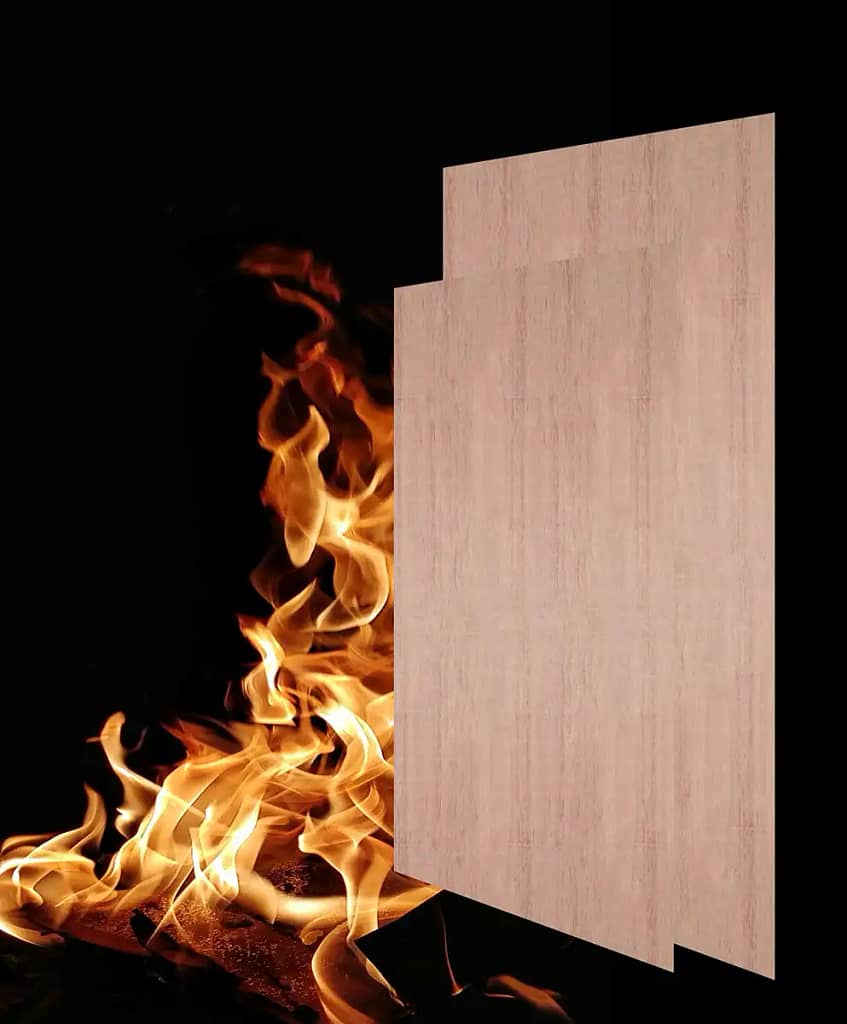

Fire Retardant (FR) Plywood:

- This type of plywood is designed to be used in areas where fire safety is a concern.

- IS 5509 is the Indian Standard for FR plywood.

The best plywood for the Kitchen is BWP ( BIS: IS 701 with FR resistance, BIS: IS 5509).

Tip #2: Look for BIS Certification Marks

Another way to verify the quality of marine plywood is to look for certification marks from the Bureau of Indian Standards (BIS) or the International Organization for Standardization (ISO). These marks indicate that the plywood has been tested and meets the required standards.

Tip #3: Plywood thickness and the number of plies:

The thickness and number of plies used in the plywood can affect its strength and durability. A good brand of marine plywood is more likely to use a sufficient number of high-quality plies and to adhere to strict thickness tolerances to ensure consistent performance. A poor brand may use fewer plies or thinner plies, resulting in a weaker and less durable product.

Tip #4:Adhesive quality & process

The quality of the adhesive used to bond the plies together is crucial to the performance of marine plywood. A good brand of marine plywood is more likely to use high-quality, waterproof adhesives that are resistant to delamination and decay. A poor brand may use lower-quality adhesives that may fail over time, resulting in a weaker and less durable product.

There are three common methods of pasting:

- Contact Adhesive Method

- Solvent-based Adhesive Method

- Double-sided Tape Method:

Out of these methods, the contact adhesive method is considered the best for pasting laminate sheet on ply as it creates a strong, durable bond that can withstand the stresses and strains of everyday use. Additionally, this method allows for precise placement of the laminate sheet, which is important for achieving a clean and professional-looking finish. In this method, both the surface of the plywood and the back of the laminate sheet are coated with a special type of contact adhesive. The adhesive is allowed to dry until it is tacky, and then the laminate sheet is carefully placed onto the plywood surface. Once the laminate is in position, a roller is used to apply pressure evenly across the entire surface of the sheet.

Tip #5: Process of pasting the laminate to the Ply:

The laminate can be pasted to the ply by either of the two methods:

Mechanical machine pasting involves the use of a specialized machine that applies the adhesive and the laminate sheet to the plywood surface. The machine is designed to ensure precise placement and even pressure across the entire surface of the laminate sheet. This method is faster and more efficient than manual pasting, making it suitable for larger projects.

Manual pasting involves applying the adhesive and the laminate sheet to the plywood surface by hand. This method requires more time and effort than mechanical machine pasting but can be more precise and flexible. Manual pasting allows for more control over the placement of the laminate sheet, and it is easier to make adjustments and corrections during the pasting process.

Tip #6: Brand of Marine Ply

- Wood species and grade: The quality of the wood used to make the plywood can vary depending on the species and grade of the wood. A good brand of marine plywood is more likely to use high-quality, durable wood species that are resistant to rot and insects, such as teak, mahogany, or oak. A poor brand may use lower-quality or inferior species of wood that are more prone to rot or insect damage.

- Water Resistance: A good brand of marine plywood is more likely to have undergone thorough water resistance testing and to meet or exceed industry standards for water resistance. A poor brand may not have undergone adequate testing or may not meet industry standards, resulting in a product that is less resistant to water damage.

Tip #7: Information Concealed by Vendor

Often the vendors conceal their weaknesses to sell. Here are a few of the ways they conceal information on Marine Ply:

Use of different Ply for Lower and Upper Kitchen Units: A Vendor provides the lower unit of BWP Marine Ply and the upper unit of MDF Ply and announces that they provide BWP Marine Ply, keeping silent that they are giving upper carcass of MDF Ply.

Providing incomplete information:

- The vendors simply tells customer that they are giving water proof ply or Marine Ply, keeping silent on whether it is BWP (Boiling Water Proof) or BWR (Boiling Water Resistant) or MR (Moisture Resistant). They also don’t provide information on whether the ply is FR (Fire Resistant or not).

- The vendors provide non-ISI marked Marine Ply, which is not tested for the BIS standards specification.

In conclusion, marine plywood is an essential component of modular kitchens, but not all marine plywood is created equal. Vendors may try to deceive customers by making false claims, but by following the tips provided by experts, you can ensure that you are getting high-quality marine plywood for your modular kitchen. Verify the quality of the plywood, look for certification marks, check the vendor’s reputation, ask for detailed information, and consider hiring an expert if needed. With these precautions, you can avoid being fooled by marine plywood claims in modular kitchens.